We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

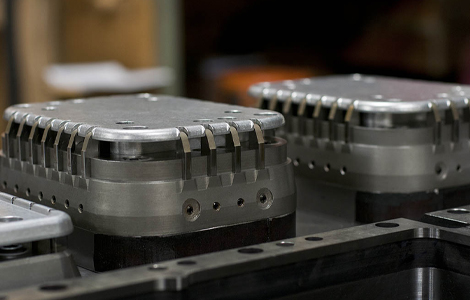

Trim tools that perform well over an extended period must be manufactured from the finest materials, using well established manufacturing procedures. At ODC, die sets are manufactured in-house utilizing surface ground shoes plus class one fit pins and bushings. Punch and die components are precision machined/ground utilizing high carbon tool steels, double/triple draws, vacuum heat treating and finally precision alignment of the punch/die components. All tools are press proven at ODC thereby ensuring that both tool functionality and production readiness have been achieved.

Our trim tool experience has evolved to include many pre-punch and progressive (two stage) trim applications. Progressive trim tooling is commonly required on tamper evident containers which are increasingly common. These demanding applications require trim equipment that is accurate and well maintained. Tooling technicians will work on your production floor assisting your staff in press inspections, tool setting and tool/machine maintenance. Attention to all details, including part registration, off fall (scrap) handling and part stacking must be considered for the successful launch of any new product. ODC is ready to assist you on your most demanding applications.