We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

ODC will test cut your unique acoustical, cover stock or substrate materials to establish the correct cutting clearance to produce the cleanest possible trimmed parts. Evaluation of your material with recommended cutting clearance will be established. There is no charge for this service and it is representative of ODC's partnering approach to gaining your business and achieving outstanding results.

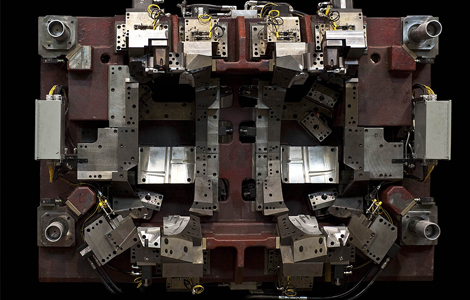

Working with your parts designer from the earliest possible moment, ODC sales engineers will massage CAD data and suggest improvements to part geometry that make the part more "trim friendly". Once good part data and runoff are developed ODC will utilize CATIA V5 to design the trim tool. ODC makes extensive use of the casting process to reduce tool cost and weight while providing excellent tool rigidity. All aspects of the production environment and process are considered from tool/part loading, to slug clearance and scrap conveying.

Our industry leading team is ready to assist you on your most demanding trim applications.